Use CCS' expert CS-2500 Level 5 to take full advantage of all functions on all models of Stokes tablet presses or adapt the CS-2500 Control System to any tablet press made by any OEM including Fette, Korsch, Hata and others.

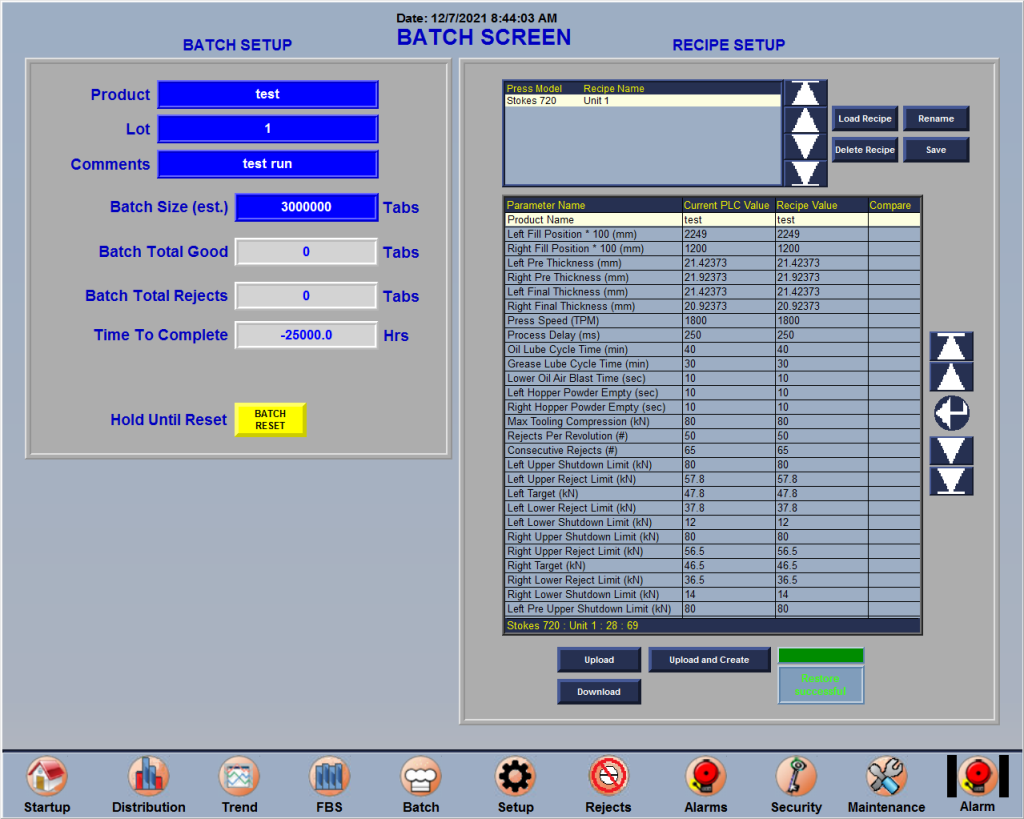

In addition to providing standard press controls found on the CS-2000 Control System, the CS-2500 features the ability to generate detailed reports -- storing production data, parameter changes/audit trail, and current and historic alarms. These reports can be organized and divided into sub-groups such as interlocks, process, and machine reports. The CS-2500 can generate custom reports to track specific information required by your application.

A development license of XLReporter by SyTech is included with all systems so that end users can create and customize their own reports.

This control system has been designed with the latest technology using off-the-shelf components resulting in a system that is easy to operate and maintain. Using Allen Bradley ControlLogix PLCs and Factory Talk View HMI software interface, the system provides complete control of the tablet press. The system also complies with 21 CFR Part 11 for data collection and E-Signature.

Design Features

- Production, Alarm, Audit Trail and Custom Reports using XLReporter

- 21 CFR Part 11 ‘Data Collection with Electronic Signature’ compliant

- Networking of Multiple Tablet Presses

- Remote Monitoring and Troubleshooting of PLC and HMI via VPN Web port

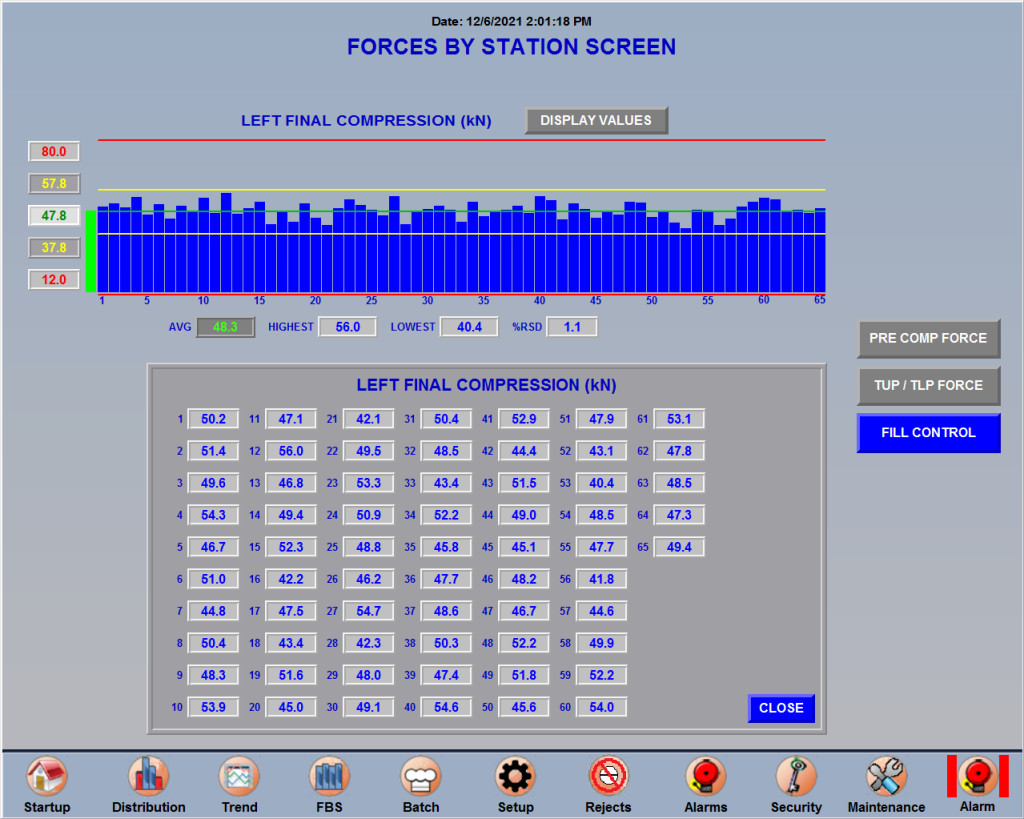

- Graphic Displays of average compression force, weight adjust limits with shutdown limits included

- Static calibration using HMI Calibration Screen

- Automated rejection of out of specification tablets with sampling

- Statistics from individual punch stations

- Punch Station force readout bar graph for each compression roll which is updated each revolution

- Distribution bar graph provides tablet weight data per batch

- Individual Control left and right side of tablet press (Production Mode On/Off) and (Weight Control On/Off)

- Multiple Security Levels (Maintenance, Supervisor and Operator)

- Alarm Summary Screen with Shutdown and Process Alarms

- Positions, Rates, Pressures and Timer Screens

- All major components used are Allen Bradley (HMI, PLC, VFD and Servo Drives)

- All programming software and documentation are included

Revolutionize tablet manufacturing with the CCS CS-2500 Level 5 Control System. This system is adept at enhancing the functionality of various Stokes models and adaptable to presses from other manufacturers like Fette and Korsch. Its standout feature is the ability to produce in-depth reports, which are essential for monitoring production data, auditing changes, and tracking alarms. These reports are highly customizable, thanks to the included XLReporter license. The CS-2500 is crafted with the latest technology, including Allen Bradley ControlLogix PLCs and Factory Talk View HMI software, ensuring complete control over tablet presses. It's not just about efficiency; this system also ensures compliance with regulatory standards such as 21 CFR Part 11, making it a reliable choice for quality and safety in tablet production.